How to avoid chocolates break?

- Andy Lau

- Nov 12, 2021

- 3 min read

Updated: Feb 12, 2022

Table of Contents

For holidays, anniversaries, or even just a fun Friday night, people all around the

world enjoy delicious candies to make their lives a little sweeter. Candy lovers

mostly focus on how each product tastes; however, not everyone realizes just how

important high-caliber candy packaging is to keep these goods safe and maintain

positive associations with the brand.

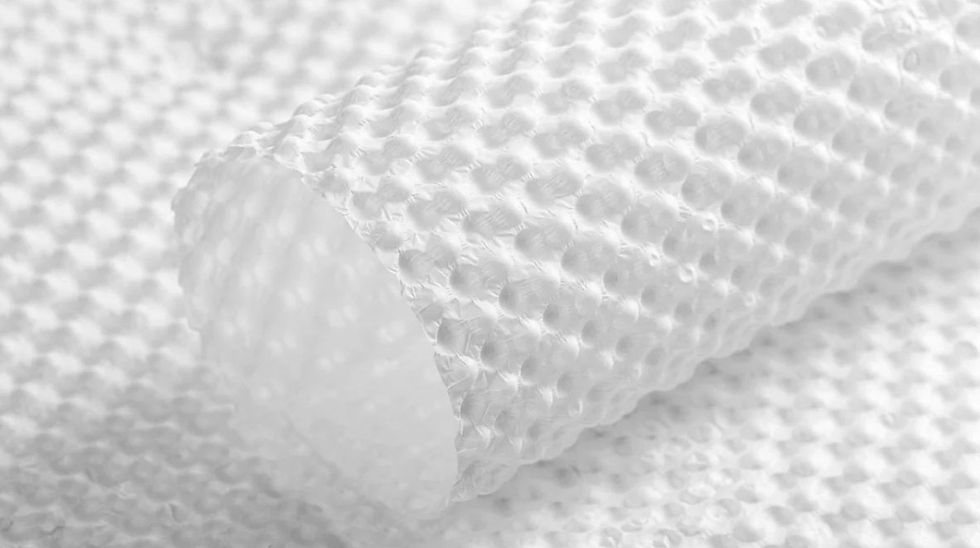

But how do candy companies keep chocolates from breaking and reach customers safely?

The answer is simpler than you think---- candy pads. Here are a few ways that candy pads have revolutionized the candy industry as a whole.

source: Michael Package

Why Use Candy Pads?

When packaging chocolates or other products, manufacturers must do everything in their power to prevent these delicate treats from being damaged in transit and

when sitting on tall shelves in stores.

No customer would ever be happy with unwrapping the box from their favorite

chocolate brand, only to discover that the chocolate is crushed, crummy, or sticky on the inside. They would return it right away. That's why these paper cushions are

designed to protect the goods inside candy boxes throughout the entire distribution process. When customers finally get ahold of chocolate that's come from hundreds of miles away, it will be in the same condition as when it left the distribution site.

Candy pads also separate chocolate by creating protective layers between each

chocolate so that piece maintains its flavor. Candy pads are customizable to suit

every box shape and company's design preferences. Businesses can choose between several layer types with customized thickness, including:

• 3-ply

• 5-ply

• 7-ply

• 9-ply

source: Michael Package

Flexography on Candy Pads

One way that creates the perfect candy packaging is through flexography.

Flexography, or Flexo printing, is a process that prints from a flexible relief plate. It

can be printed on almost any material like plastic, metallic, cellophane, and paper.

This process is ideal for food safety because it uses food-safe inks, so candy

companies don't have to worry about their customers ingesting toxic printing

materials when enjoying their candy.

Flexography is a great way to print on packaging and reinforce a brand's identity.

This is a great tool for brands who are looking to revamp their product marketing

and maintain a high-quality pad while simultaneously placing a high value on

aesthetics. The process of flexography also requires fewer resources and energy to print, making this printing solution much more eco-friendly than other methods.

source: Michael Package

Eco-Friendly Materials

Candy companies are feeling the pressure to find eco-friendly packaging solutions

for their products without compromising on safety, quality, and brand identity.

However, cushion pads make that search easy. They're made of glassine paper,

which is food-grade, recyclable, and made in a dust-free plant. This makes these

cushion pads not only safe to touch food directly, but also safe for the environment.

Glassine paper also brings production benefits because it isn't greasy. It's also highly resistant to damage and nonabsorbent, protecting the product from any external moisture and keeping the packaging in immaculate shape.

source: Michael Package

Every Manufacturer Needs Candy Pads

Candies, cookies, and chocolates are the little things that make a big impact on

peoples' lives. Although candy pads may seem like a small thing to consider, it plays a huge part in creating customer satisfaction. They also make packaging much easier for businesses, as they're durable, nonabsorbent, customizable, and eco-friendly.

With the right candy pad manufacturer, a business will elevate their or products,

who appreciate undamaged goods and the freshest chocolate possible when they

open their order.

If you are looking for a new and improved way to package your products with candy

pads, we recommend visiting Michael Package's website to learn more.

Comments